CNC Machining China

Get instant quotes on custom metal and plastic machined parts with our Online CNC Machining Service. Make quick turn prototypes and production parts in days with free standard shipping on all US orders. ISO 9001:2015, ISO 13485 and AS9100D certified. ITAR registered.

Make your product a reality and meet all customer expectations. We turn your drawings into well-made parts using CNC milling, turning, and other manufacturing technologies.

- All uploading files are secure and confidential.

20+Years

Manufacturing experience

1000+Customers

Over the world

8M+Parts

Custom Machined

99.8%

Good Feedback

Our Manufacturing Capabilities

Shangwei InnovateTech Precision Machining Ltd provides high-quality prototyping, low and large-volume manufacturing services to support your product development needs. Our international team will work with you to make your product ideas a reality through high-tech CNC equipment and ensure your parts are shipped on time.

If you’re looking for the right CNC machining services in China, we’re your best choice!

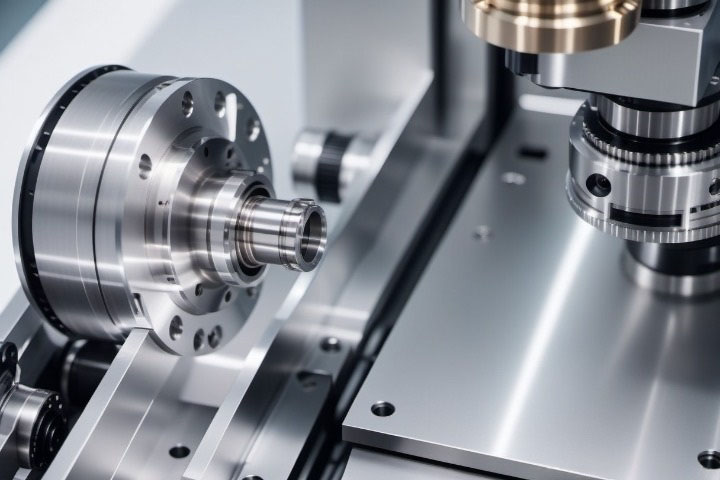

CNC Machining

Our top-notch CNC machining services create custom parts with incredible accuracy and speed. It's super efficient, precise.

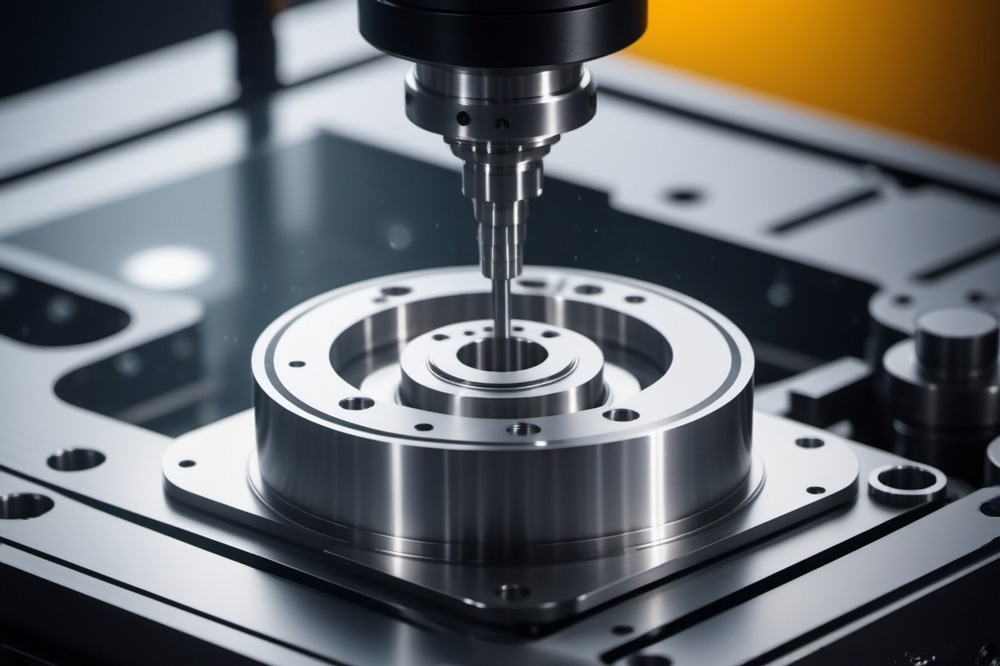

CNC Milling

Unlock the potential of your designs with our CNC milling service. Experience unmatched accuracy and efficiency for your machining needs.

Sheet Metal Fabrication

Prototyping your parts involves sheet metal cutting, welding, and forming processes. We achieve precise manufacturing with tight tolerance of ±0.05 mm.

Surface Finishing

Make your CNC-machined parts look and perform better with our special surface finishing options. We offer various techniques like polishing, bead blasting, etc.

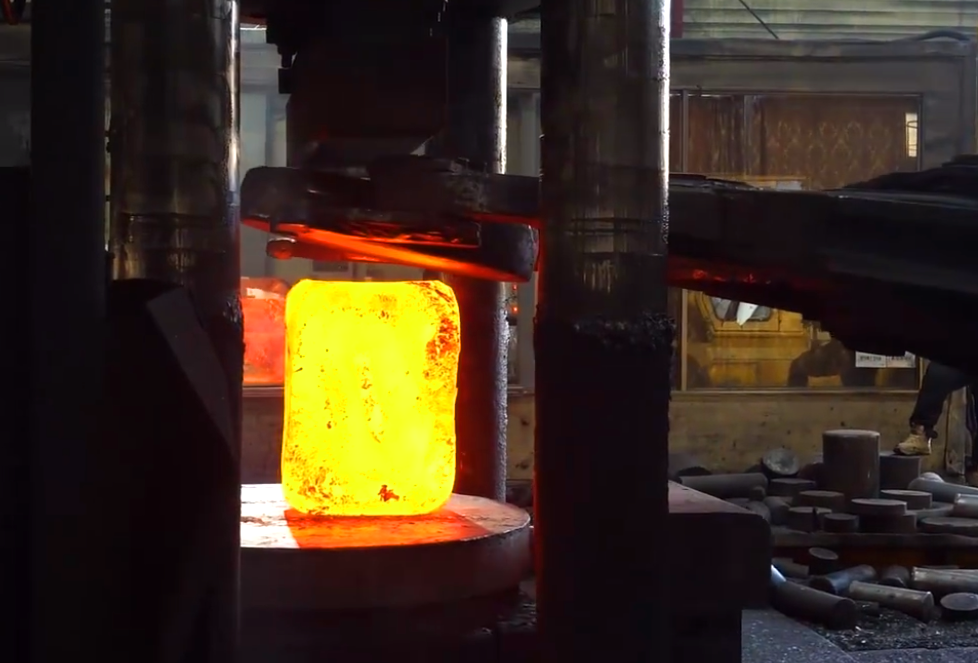

CNC Forging

Enhance the strength and performance of your components through metal forging processes. We offer support for smith forging, press forging, roll forging, etc.

CNC Injection Molding

Benefit from our plastic molding or rubber molding services, which offer a variety of materials to choose from, including ABS, PP, and PE.

Showcase of CNC Machining Parts

Manufacturing Your Parts

Upload Your Files

Upload your CAD file online to get an instant guaranteed quote and automated DfM feedback.

DFM Analysis and Quotation

Upload your CAD file online to get an instant guaranteed quote and automated DfM feedback.

Manufacture the Parts

Pay with popular and secure payment methods Avg.Lead Time 2 days

Arrange the Shipping

Easily manage orders online, track deliveries and share important details with others on your team.

Applications Industry

CNC Machining for Automotive Industry

CNC machining is vital in the automotive industry for its precision and efficiency in manufacturing various components:

- Prototyping: Enables testing of parts before mass production.

- Engine Components: Produces precise parts like cylinder heads, pistons, and crankshafts.

- Transmission Parts: Creates gears, shafts, and housings with strict tolerances.

- Chassis and Suspension: Fabricates durable components like control arms and steering knuckles.

- Interior and Exterior Trim: Forms intricate parts such as dashboard panels and grilles.

- Tooling and Fixtures: Manufactures molds, dies, jigs, and fixtures for production processes.

- Customization: Allows for tailored performance upgrades and aftermarket parts.

- Material Versatility: Works with diverse materials including aluminum, steel, and plastics.

In essence, CNC machining ensures precise, flexible, and high-quality production essential for automotive manufacturing.

CNC Machining for Semiconductor Industry

CNC machining plays a crucial role in the semiconductor industry, where precision and reliability are paramount. Here’s a brief overview:

- Precision Manufacturing: CNC machining is utilized to produce intricate components with extremely tight tolerances required for semiconductor equipment and devices.

- High-Quality Materials: It enables the machining of various materials used in semiconductor manufacturing, including silicon, ceramics, and metals, ensuring optimal performance and longevity.

- Customization and Prototyping: CNC machining allows for rapid prototyping and customization of parts, facilitating the development of new semiconductor technologies and equipment.

- Efficiency and Consistency: CNC technology ensures consistent quality and repeatability, vital for the mass production of semiconductor components with minimal defects.

CNC Machining for Aerospace Industry

CNC machining is indispensable in the aerospace industry for its precision, reliability, and versatility. Here’s a concise overview:

- Complex Component Production: CNC machining is used to manufacture intricate components such as turbine blades, aircraft structural parts, and engine components with high precision and tight tolerances.

- Advanced Materials Machining: It enables the machining of advanced materials like titanium, composites, and superalloys essential for aerospace applications, ensuring optimal performance and durability.

- Weight Reduction and Optimization: CNC technology allows for the creation of lightweight yet durable components, contributing to fuel efficiency and overall aircraft performance.

- Strict Regulatory Compliance: CNC machining ensures compliance with stringent aerospace regulations and standards, guaranteeing the safety and reliability of aircraft components.

- Rapid Prototyping and Iteration: CNC machining facilitates rapid prototyping and iteration of aerospace parts, accelerating the development process and enabling innovation in aircraft design and performance.

CNC Machining for Agriculture Industry

CNC machining plays a pivotal role in the agriculture industry, offering precision and efficiency for various applications. Here’s a succinct overview:

- Equipment Manufacturing: CNC machining is instrumental in producing agricultural equipment such as tractor components, harvesters, and irrigation system parts with high precision and durability.

- Customization and Adaptability: It enables the customization of agricultural machinery to suit specific farming needs and varying field conditions, enhancing productivity and efficiency.

- Part Replacement and Repair: CNC technology facilitates the production of replacement parts and components for agricultural machinery, ensuring minimal downtime and uninterrupted operations.

- Innovative Solutions: CNC machining allows for the development of innovative solutions such as precision planting equipment and autonomous farming systems, advancing agricultural practices and sustainability.

- Material Compatibility: CNC machining accommodates a wide range of materials used in agriculture, including steel, aluminum, and plastics, ensuring compatibility with diverse farming environments and requirements.

CNC Machining for Medical Industry

CNC machining is vital in the medical industry, providing precision manufacturing solutions for various applications. Here’s a concise overview:

- Medical Device Production: CNC machining is used to manufacture medical devices such as surgical instruments, implants, and prosthetics with exceptional precision and quality.

- Customization and Patient Specificity: It enables the customization of medical implants and devices to match individual patient anatomy, improving patient outcomes and comfort.

- Biocompatible Materials: CNC technology works with biocompatible materials such as titanium, stainless steel, and medical-grade plastics, ensuring safety and compatibility with the human body.

- Rapid Prototyping and Iteration: CNC machining facilitates rapid prototyping and iteration of medical devices, accelerating the development process and enabling innovation in healthcare technology.

- Strict Quality Standards: CNC machining adheres to strict regulatory standards and quality control measures, guaranteeing the reliability and performance of medical components essential for patient safety.

CNC Machining for Energy Industry

CNC machining is indispensable in the energy industry, providing precision manufacturing solutions for various applications. Here’s a succinct overview:

- Component Fabrication: CNC machining is crucial for producing components used in energy generation, transmission, and storage systems, such as turbine blades, solar panel frames, and battery casings.

- High-Quality Materials: It enables the machining of materials like stainless steel, aluminum, and specialized alloys used in energy equipment, ensuring durability and performance in demanding environments.

- Efficiency Optimization: CNC technology allows for the fabrication of complex components with optimized designs, enhancing the efficiency and reliability of energy systems.

- Customization for Renewable Energy: CNC machining facilitates the customization of parts for renewable energy technologies like wind turbines and solar panels, supporting the transition to sustainable energy sources.

- Adherence to Standards: CNC machining adheres to rigorous quality and safety standards, essential for the reliable operation of energy infrastructure and the prevention of environmental hazards.

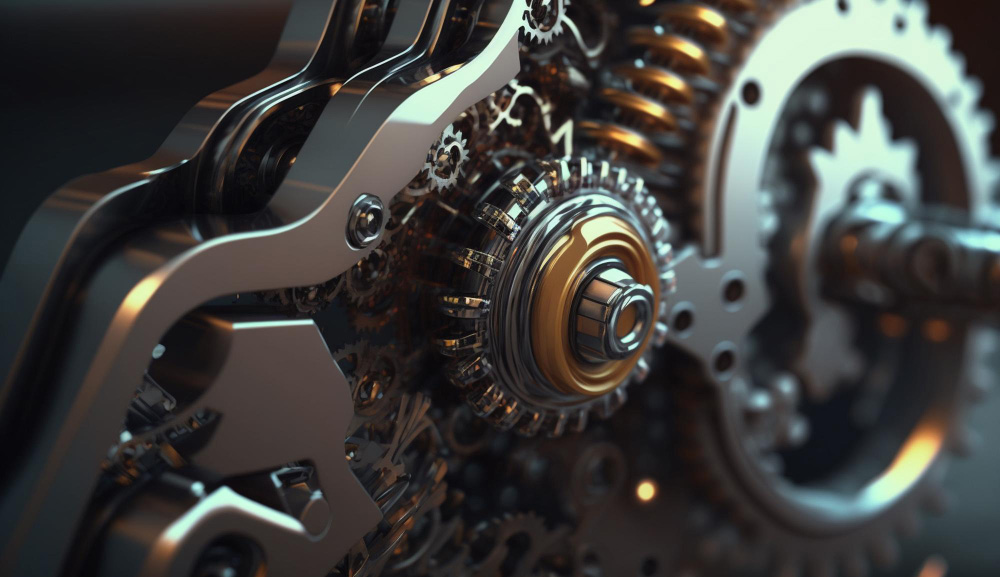

CNC Machining for Robotics Industry

CNC machining plays a pivotal role in the robotics industry, offering precision manufacturing solutions for various applications. Here’s a succinct overview:

- Component Fabrication: CNC machining is vital for producing precision components used in robotic systems, including gears, joints, and structural frames.

- Material Versatility: It enables the machining of materials such as aluminum, steel, and engineering plastics, providing flexibility to meet the diverse needs of robotic applications.

- Complex Geometry: CNC technology allows for the fabrication of intricate parts with complex geometries, essential for optimizing the performance and functionality of robotic systems.

- Rapid Prototyping and Iteration: CNC machining facilitates rapid prototyping and iteration of robotic components, accelerating the development process and fostering innovation in robotics.

- Quality Assurance: CNC machining ensures consistent quality and reliability in robotic components, critical for the precision and durability required in robotic operations.

Ready to bring your designs to life?

About Us

Our firm is a professional manufacturer dedicated to offering high-quality rapid prototyping and mass manufacturing services, including CNC machining, die casting, 3D printing, rapid tooling and injection molding, sheet metal prototyping, and integrating the design and development of new products.

We offer the best in CNC machining China. Our advanced on-demand manufacturing capabilities and wide selection of quality materials make us the perfect partner for any industry seeking reliable, best-in-class products. Our products are designed to meet precise specifications, ensuring superior quality and reliable functionality. From CNC machining China to production.

Feedback from Our Clients